HotKeywords: Sandpaper series ,

Selection of polishing wax for different polishing processes

Polishing wax is mainly used in conjunction with hemp wheel cloth wheel and wind wheel to polish workpieces. Different colors of polishing wax also vary. Choosing the correct polishing wax can enhance the polishing effect.

Polishing can be divided into coarse polishing, medium polishing, fine polishing, and fine polishing. The general material for rough polishing is alumina micropowder, which is used to remove wrinkles or rough skin on the surface of flat workpieces. For example, for rough polishing of stainless steel workpieces, purple wax with strong cutting force can be selected, combined with a hemp wheel. This operation will produce light quickly, have good waxing performance, and have strong cutting force and durability.

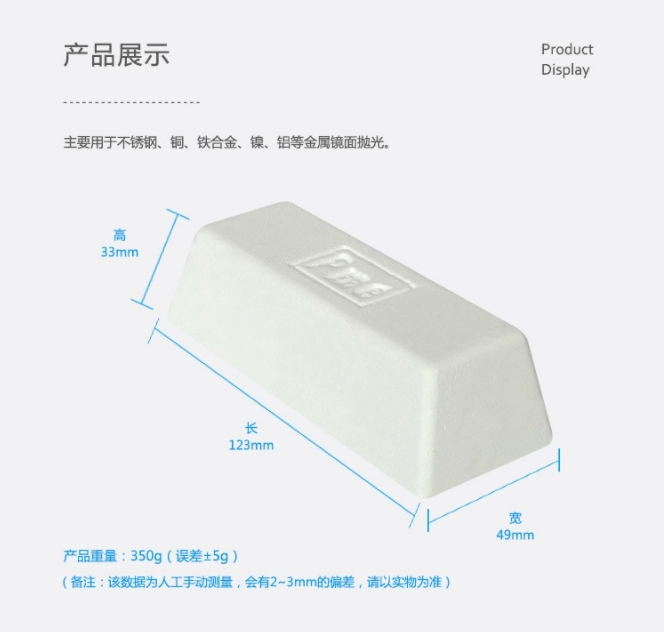

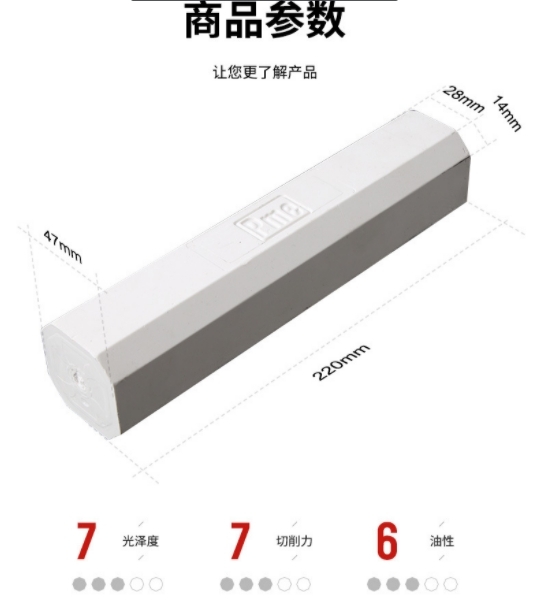

Middle polishing is slightly different from rough polishing. It is necessary to remove the lines left during rough polishing, and to achieve a deeper leveling effect on the surface of the workpiece. At this time, it is possible to choose middle polishing with white wax and cloth wheels to cast light on the workpiece, ensuring cutting force while obtaining better glossiness.

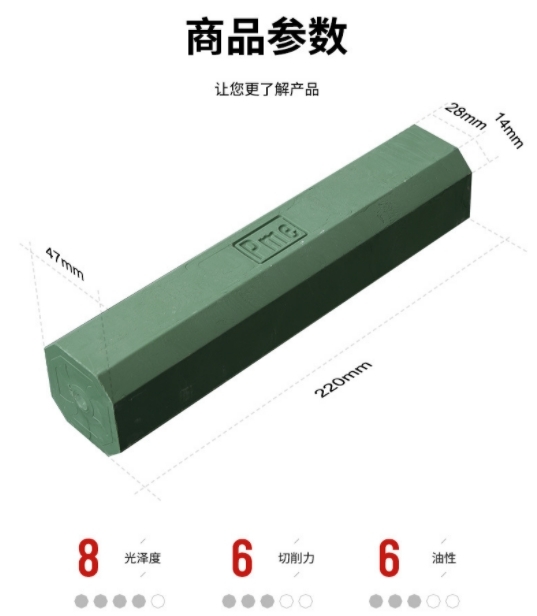

Fine polishing is an important step in order to achieve a high gloss or mirror effect on the product. At this time, green wax is used in conjunction with a cloth roller to achieve a high gloss and flat surface of the workpiece. Green wax belongs to fine polishing wax, which has good cutting force and higher glossiness and oiliness.

Fine polishing is the final process of polishing and also the process of mirror processing. It uses mirror light small white wax and is polished together with a cloth roller, which can maximize the surface gloss of the workpiece.