HotKeywords: Sandpaper series ,

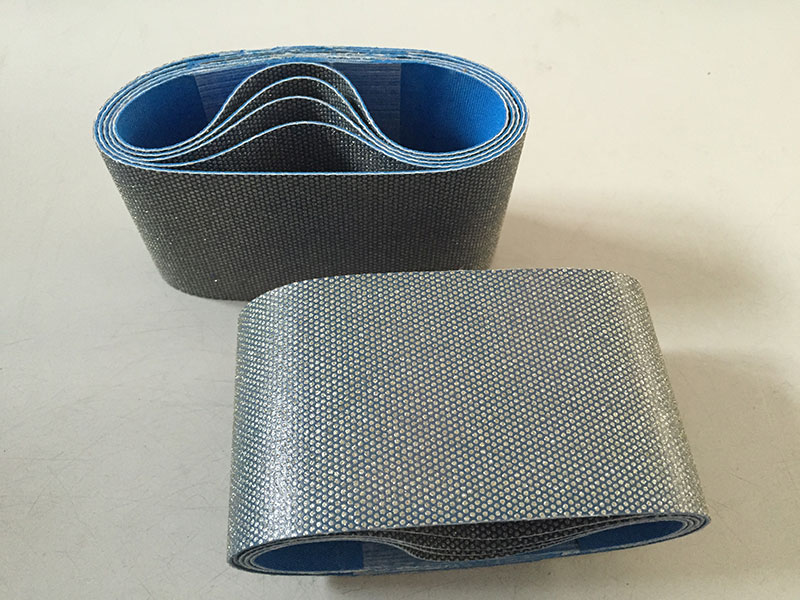

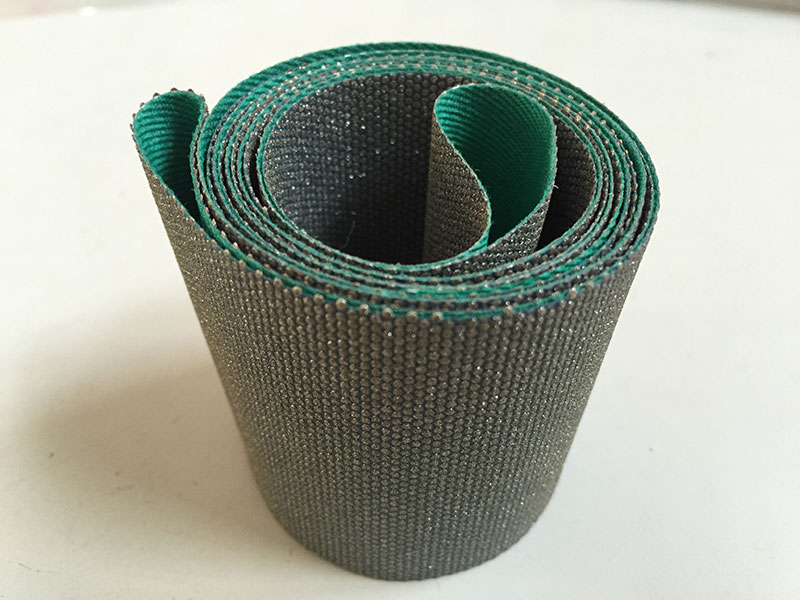

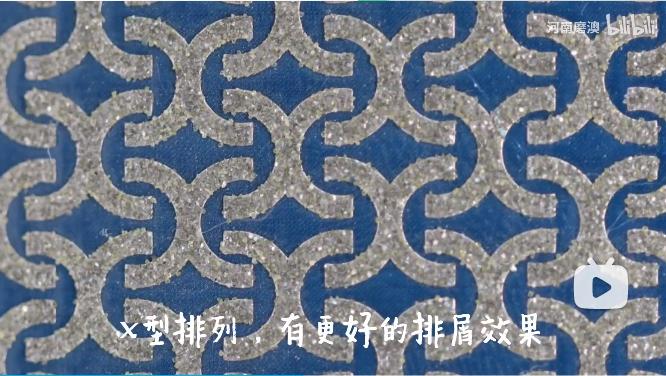

Electroplated diamond sand belt

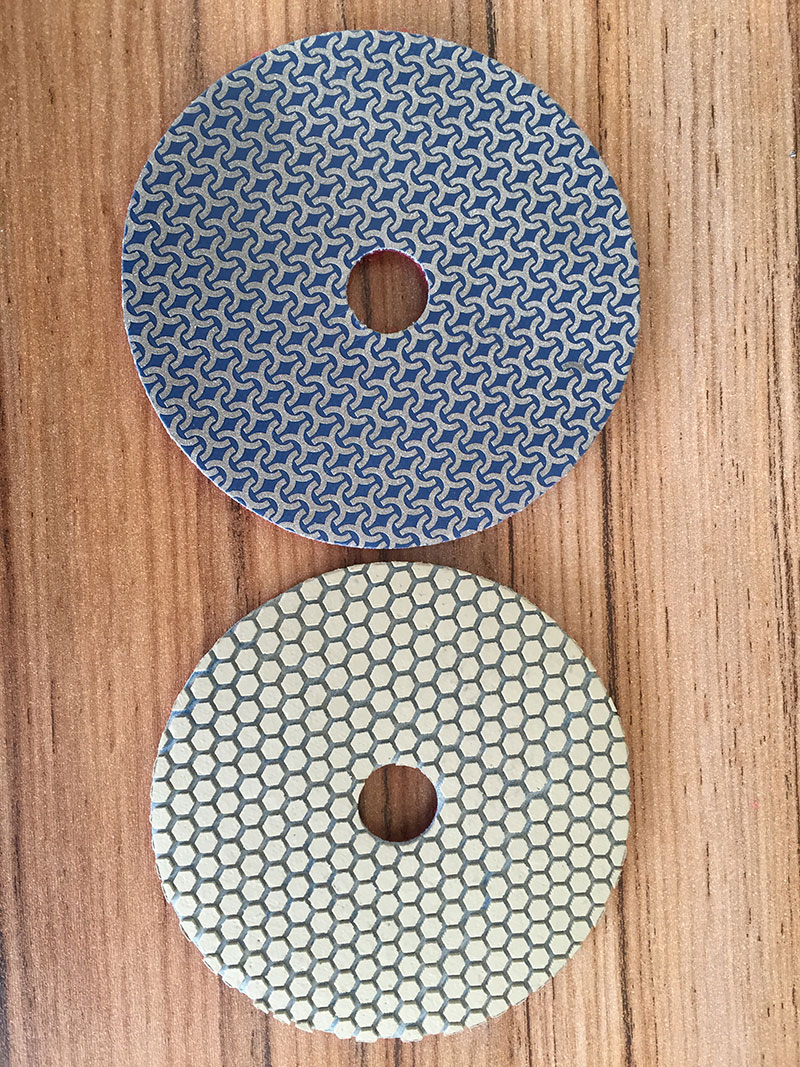

① X-shaped arrangement for better chip removal effect (anti clogging)

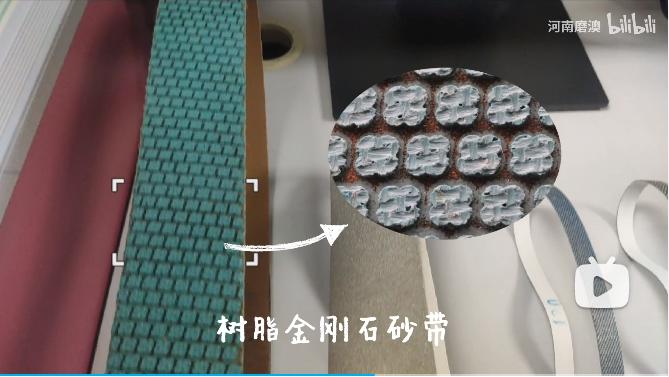

② Resin diamond abrasive belt for better polishing effect and less prone to scratches

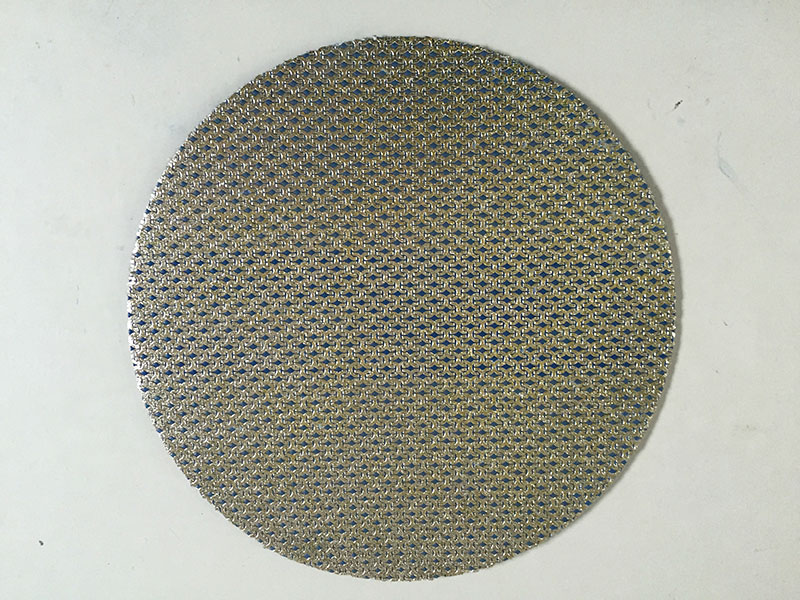

Resin fully coated abrasive belt This type of abrasive belt is used to evenly coat the resin on the entire substrate surface, so that the abrasive is distributed on the entire plane of the cloth substrate with a certain density. There are two methods for manufacturing this type of abrasive tape: manual coating and mechanical coating. Due to the long service life and small production scale of diamond abrasive belts, in order to reduce equipment costs, manual coating or semi manual and semi mechanical manufacturing processes can be adopted when there are no requirements for performance. Due to the inability to control the uniformity of abrasive and adhesive coating, as well as the discontinuous production process, the manual coating process results in uneven thickness, uneven distribution, and uneven orientation of abrasive on the working surface of the abrasive belt, resulting in low product quality;

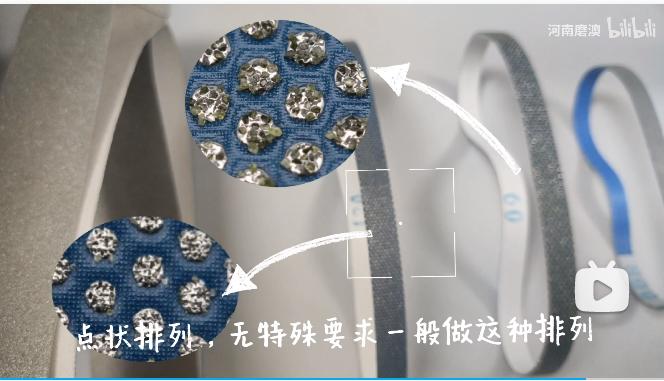

③ Disordered arrangement, with more diamond coverage

Electroplated sand tape is a common type produced by domestic and foreign manufacturers, mainly due to its simple production equipment, high bonding strength, adhesive wear resistance, and temperature resistance compared to resin. However, further research is needed to solve the problems of substrate strength and substrate joint strength of electroplating closed sand tape.

④ Point shaped mine clearance, generally arranged in this way without special requirements

Resin dispensing products have simpler manufacturing equipment and lower equipment investment compared to coated products, and the dispensing type can improve the overall flexibility of resin coated products due to the brittleness and hardness of ordinary resin after curing. In addition, dispensing products can perform better grinding performance when grinding hard plastic materials or dry grinding due to their evenly distributed gaps in the middle.

Diamond abrasive belt products can be widely used in the grinding and polishing of complex shapes of hard and brittle materials such as stone, glass, ceramics, monocrystalline silicon, polycrystalline silicon, synthetic materials, hard alloys, aluminum alloys, etc.