HotKeywords: Sandpaper series ,

polishing

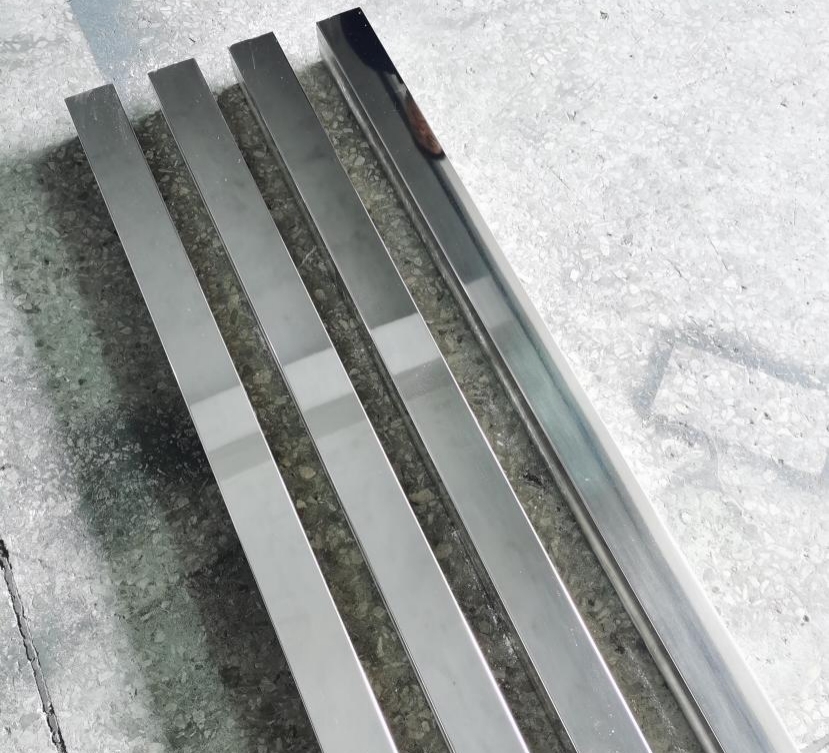

Polishing refers to the process of using mechanical, chemical, or electrochemical effects to reduce the surface roughness of a workpiece, in order to obtain a bright and flat surface. It is the use of polishing tools and abrasive particles or other polishing media to modify the surface of the workpiece.

Polishing cannot improve the dimensional or geometric accuracy of the workpiece, but rather aims to obtain a smooth surface or mirror gloss, sometimes used to eliminate gloss (extinction). Usually, polishing wheels are used as polishing tools. The polishing wheel is generally made by stacking multiple layers of canvas, felt, or leather, with metal circular plates clamped on both sides. The rim of the wheel is coated with a polishing agent composed of a uniform mixture of micro abrasive and grease.

During polishing, a high-speed rotating polishing wheel (with a circumferential speed of over 20 meters/second) presses against the workpiece, causing the abrasive to roll and perform micro cutting on the surface of the workpiece, thereby obtaining a bright machining surface. The surface roughness can generally reach Ra0.63-0.01 micrometers; When using a non greasy matte polishing agent, it can dull the bright surface to improve its appearance. When producing bearing steel balls in large quantities, the method of drum polishing is often used.

During rough polishing, a large amount of steel balls, lime, and abrasives are placed in an inclined drum. When the drum rotates, the steel balls and abrasives randomly roll and collide within the drum to remove surface protrusions and reduce surface roughness. This can remove approximately 0.01 millimeters of excess.

During precision polishing, steel balls and fur fragments are loaded into a wooden barrel and continuously rotated for several hours to obtain a dazzling and shiny surface. The polishing of precision line rulers is carried out by immersing the machined surface in a polishing solution, which is composed of a mixture of chromium oxide powder with a particle size of W5-W0.5 and an emulsion. The polishing wheel is made of uniformly fine wood or specially made fine felt that has undergone degreasing treatment. Its motion trajectory is a uniform and dense network, and the surface roughness after polishing is not greater than Ra0.01 micrometers. No surface defects can be observed under a 40 times magnification microscope. In addition, there are Electropolishing and other methods.

How to polish

1. Mechanical polishing Mechanical polishing is a polishing method that uses cutting and plastic deformation of the material surface to remove the protrusions after polishing to obtain a smooth surface. It generally uses oilstone strips, wool wheels, sandpaper, etc., and is mainly manually operated. Special parts such as the surface of the rotating body can use auxiliary tools such as a turntable. For high surface quality requirements, ultra precision polishing can be used. Ultra precision polishing is the use of specially designed grinding tools, which are tightly pressed onto the machined surface of the workpiece in a polishing fluid containing abrasives and perform high-speed rotational motion. By utilizing this technology, Ra0.008 can be achieved μ The surface roughness of m is the highest among various polishing methods. This method is often used in optical lens molds.

2. Chemical polishing Chemical polishing is the process of preferentially dissolving the concave parts of a material's surface that protrude from the surface in a chemical medium, thereby obtaining a smooth surface. The main advantage of this method is that it does not require complex equipment and can polish workpieces with complex shapes. It can simultaneously polish many workpieces with high efficiency. The core issue of chemical polishing is the preparation of polishing solution. The surface roughness obtained by chemical polishing is generally in the order of 10 μ M.

3. Electropolishing The basic principle of Electropolishing is the same as that of chemical polishing, that is, by selectively dissolving the small protruding parts on the surface of the material, the surface is smooth. Compared with chemical polishing, it can eliminate the influence of cathodic reaction and achieve better results. The electrochemical polishing process is divided into two steps: (1) macroscopic leveling, diffusion of dissolved products into the electrolyte, and a decrease in geometric roughness of the material surface, with Ra>1 μ M. (2) Low light level flat anodic polarization, increased surface brightness, Ra<1 μ M.

4. Ultrasonic polishing places the workpiece in an abrasive suspension and together in an ultrasonic field, relying on the oscillation effect of the ultrasonic wave to grind and polish the abrasive on the surface of the workpiece. Ultrasonic machining has low macroscopic force and will not cause deformation of the workpiece, but it is difficult to make and install tooling. Ultrasonic machining can be combined with chemical or electrochemical methods. On the basis of solution corrosion and electrolysis, ultrasonic vibration is applied to stir the solution to separate the dissolved products on the surface of the workpiece, and the corrosion or electrolyte near the surface is uniform; The cavitation effect of ultrasound in liquids can also suppress the corrosion process, which is conducive to surface brightening.

5. Fluid polishing: Fluid polishing is achieved by flushing the surface of a workpiece with a high-speed flowing liquid and its accompanying abrasive particles. Common methods include abrasive jet machining, liquid jet machining, Fluid power grinding, etc. Fluid power grinding is driven by hydraulic pressure, which makes the liquid medium carrying abrasive particles flow back and forth across the workpiece surface at a high speed. The medium is mainly made of special compounds with good flowability under low pressure and mixed with abrasives, which can be silicon carbide powder.

6. Magnetic abrasive polishing is the use of magnetic abrasives to form abrasive brushes under the action of a magnetic field to grind and process workpieces. This method has high processing efficiency, good quality, easy control of processing conditions, and good working conditions. Using suitable abrasives, the surface roughness can reach Ra0.1 μ M.