HotKeywords: Sandpaper series ,

The polishing process is generally divided into coarse polishing, intermediate polishing, fine polishing, and mirror polishing.

Rough polishing: Generally, factories use abrasive belts, thousand blade wheels, nylon wheels, or rigid grinding wheels to remove rough lines on the surface of products.

Middle polishing: Generally, hemp wheel (or wool wheel) and purple wax (black wax) are used to remove the spots and rough lines of the product, and the product is relatively smooth after polishing.

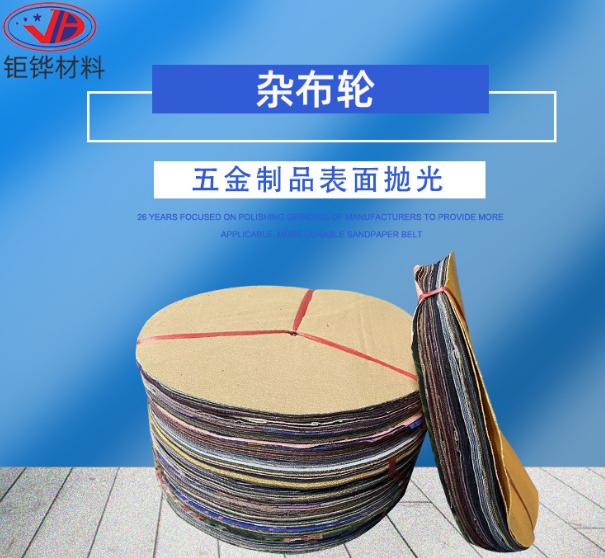

Fine polishing: Generally, coarse polishing cloth wheels (miscellaneous cloth wheels) or wind polishing (wheels)+polishing white wax or green wax are used, so that the surface of the product is relatively bright after polishing. Normal products generally have low requirements so that they can be shipped.

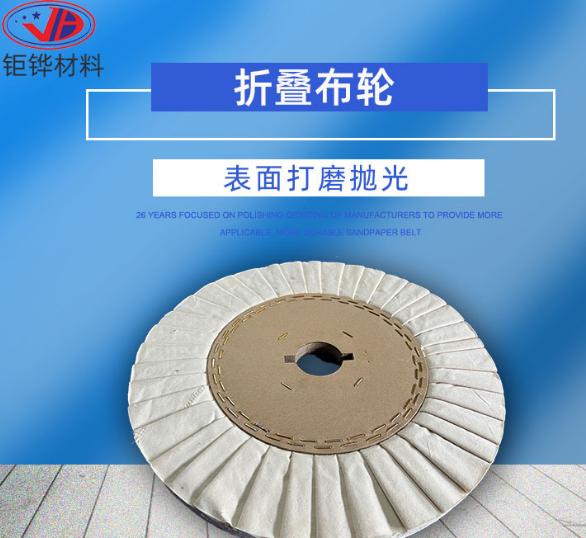

Mirror light: Generally, use bleached cotton cloth (requiring a good cloth) or wind cloth (wheel)+mirror light small white wax or small blue wax. The cloth wheel is required to be slightly loose, and the pattern is basically gone. This is the true mirror light.