1. Reasonable selection of sand belt model

The selection of sand belt model varies depending on the material and shape of various parts. The selection of sand belt model is mainly based on four aspects: product material, abrasive material, adhesive type, and sand belt joint type.

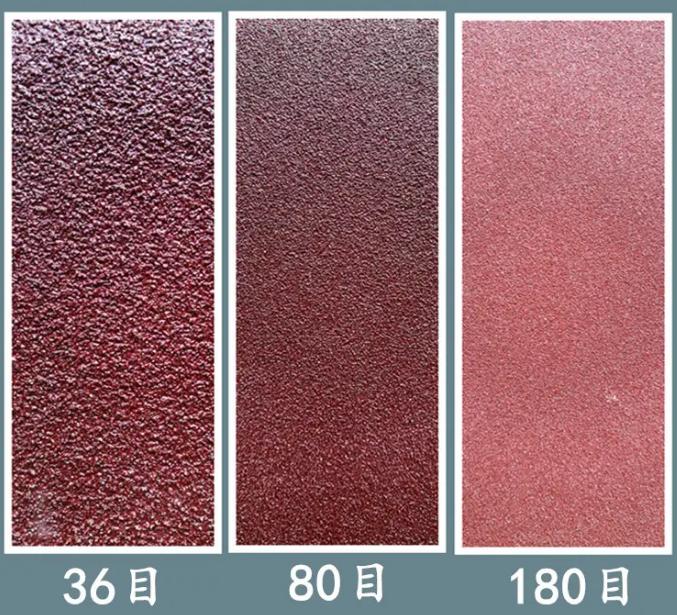

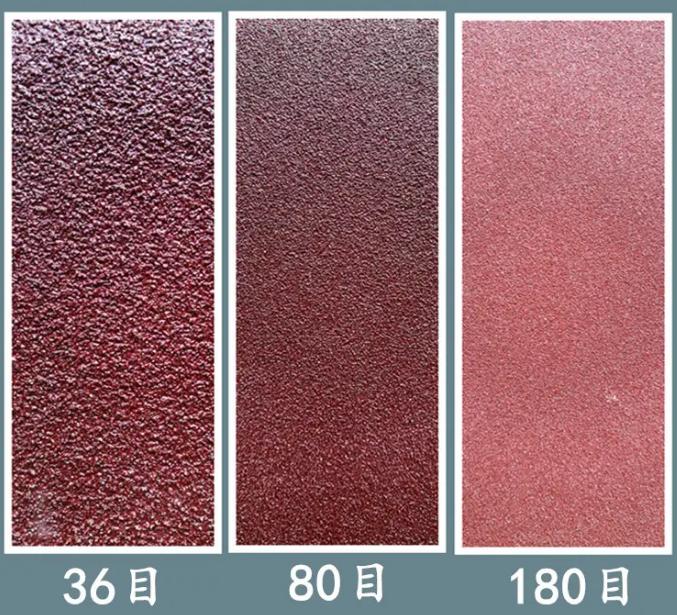

2. Choose the appropriate grit size of the sand belt

The appropriate grit size of the sand belt can improve the surface quality of the added parts and extend the service life of the sand belt. If the particle size of the selected sand belt is too large, it may affect the surface quality of the added parts; If the particle size of the selected sand belt is too large, the sand belt is prone to wrinkles and fractures during use, greatly reducing the service life of the sand belt.

3. Selection of Grinding Sequence for Multiple Sand Belt Grinding

If a product has multiple sand belt grinding processes, the subsequent process will only increase the selection of sand belt particle size by up to two particle size numbers compared to the previous process, in order to maximize the effectiveness of sand belt grinding and ensure the shape and quality of the added parts.

4. The Distribution of Grinding Amount in Multiple Belt Grinding Sequence

(1) When there are two sequences, the distribution ratio of the front and rear tracks is 85/15, which is better;

(2) When there are three sequences: the distribution ratio of the front and rear tracks is 65/25/10, which is better;

(3) When there are four sequences, it is better to have a distribution ratio of 50/30/12/8 for the front and rear tracks.

Grinding consumables, identifying Juhua materials